How Stitch-Bonded Non-Woven Fabric Could Transform the Future of Textiles

When it comes to sustainable and versatile materials, the textile industry is always on the lookout for innovative solutions. Stitchbond Non-Woven Fabric is emerging as a standout choice that could revolutionize how we approach eco-friendly textiles. So, what makes this fabric so special, and how can it benefit various industries? Let’s take a closer look.

What is Stitch-Bonded Non-Woven Fabric?

Stitch-bonded non-woven fabric is created by stitching layers of fibers together using a continuous thread. This method replaces traditional weaving or knitting and offers several unique advantages. Unlike other bonding techniques that often make the fabric stiff, stitch-bonding keeps the fibers soft and flexible while maintaining stability. As a result, the fabric remains smooth to the touch and is perfect for applications requiring a gentle surface.

Why Choose Stitch-Bonded Non-Woven Fabric?

Sustainable Production

Manufacturers are increasingly turning to recycled materials like plastic bottles (rPET) to create stitch-bonded non-woven fabric. These bottles are cleaned, shredded, and melted into fibers, reducing the need for virgin materials and lowering carbon emissions. This process not only minimizes waste but also supports a circular economy, making it an environmentally friendly choice.

Key Properties

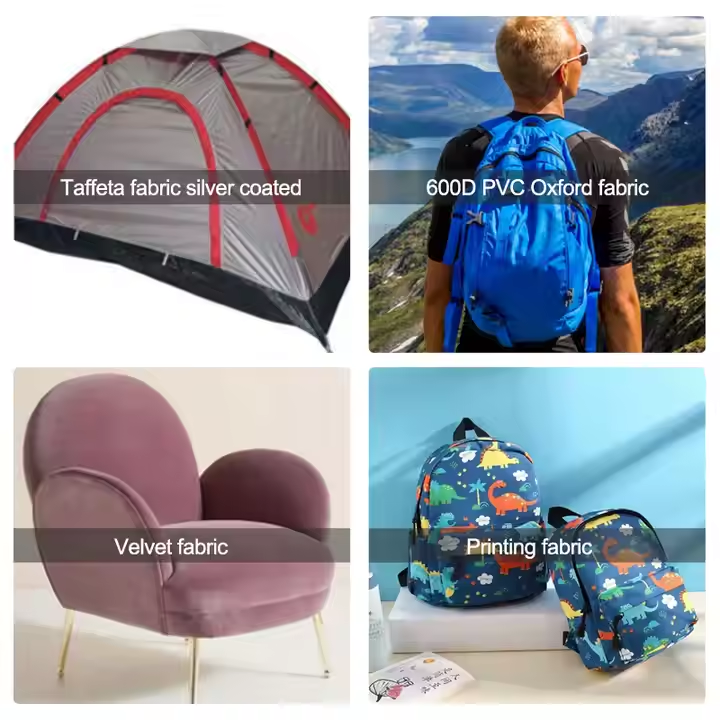

Stitchbond Non-Woven Fabric offers a wide range of textures, from soft to stiff, making it suitable for various applications. It is durable, able to withstand wear and tear, and can be customized with different treatments. For example, it can be dyed, printed, or enhanced with functional properties like waterproofing or flame retardancy.

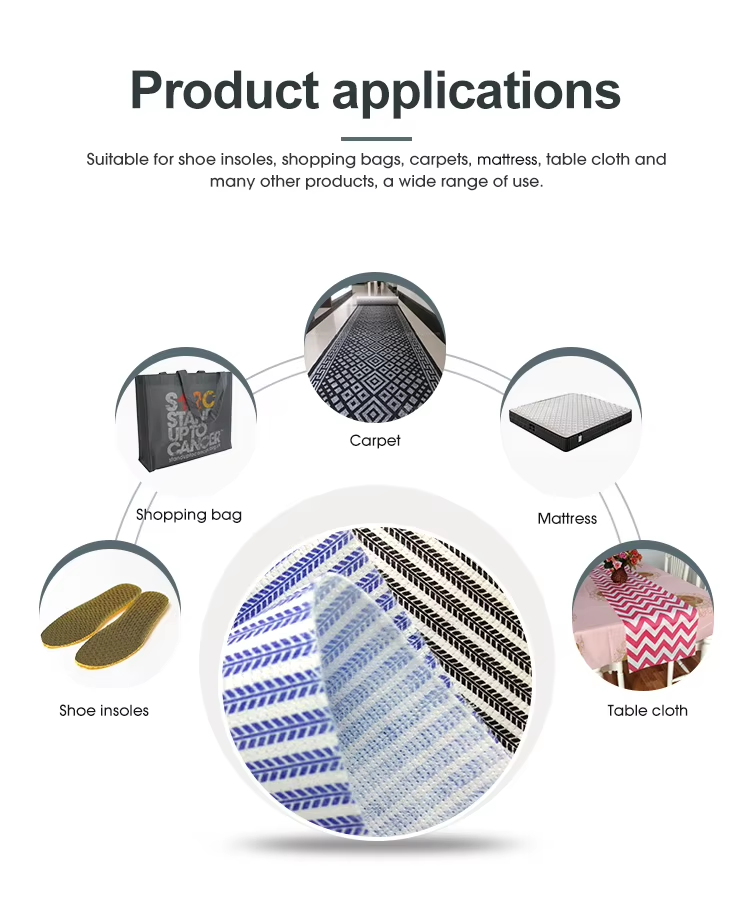

Versatile Applications

This fabric’s versatility is one of its biggest strengths. In the fashion industry, it is used for shoe linings, uppers, and midsoles, providing comfort and durability. In home textiles, it works well for curtains, upholstery, and blankets. It is also used in construction for waterproof membranes and in packaging for reusable bags. Additionally, it can be treated for specialty uses like flame retardancy or as a base for Velcro-like fasteners.

What Does the Future Hold?

As industries continue to seek sustainable and versatile materials, stitch-bonded non-woven fabric is well-positioned to meet these needs. Its ability to be produced from recycled materials, combined with its wide range of applications, makes it a promising candidate for the future of textiles. With ongoing innovations in production techniques and functional treatments, this fabric could become even more integral in reducing waste and promoting eco-friendly practices.

Conclusion

Stitchbond Non-Woven Fabric is a prime example of textile innovation. By combining softness, flexibility, and durability with a sustainable production process, it offers a compelling alternative to traditional fabrics. Whether used in fashion, home textiles, or industrial applications, this fabric has the potential to revolutionize how we think about sustainable materials. As we continue to explore new uses for this versatile fabric, its future looks bright—and so does the future of sustainable textiles.