How Does PP Spunbond Compare to Other Nonwoven Materials?

Exploring the Advantages and Environmental Impact of PP Spunbond in Today’s Manufacturing Landscape

In the world of nonwoven materials, PP Spunbond (Polypropylene Spunbond Nonwoven Fabric) has emerged as a versatile and widely-used option across various industries. But how does it stack up against other nonwoven materials? Let’s dive into the key characteristics, advantages, and environmental impact of PP Spunbond compared to its counterparts.

The Unique Attributes of PP Spunbond

PP Spunbond is created through a process called spunbonding, where polypropylene fibers are continuously extruded and bonded together without weaving or knitting. This results in a fabric that is:

-

Lightweight yet Durable: PP nonwoven is resistant to tears, punctures, and abrasions, making it ideal for products requiring strength and longevity.

-

Breathable and Versatile: The fabric allows air and moisture to pass through, making it suitable for medical, agricultural, and industrial applications.

-

Cost-Effective: Its affordability and practicality have made it a popular choice for disposable products like face masks, medical gowns, and agricultural covers.

Comparing PP Spunbond to Other Nonwoven Materials

1. Environmental Impact

While PP Spunbond offers many benefits, its environmental footprint is a crucial consideration. Unlike natural fabrics like cotton, which require vast amounts of water and pesticides, PP nonwoven uses fewer resources in production. However, it is derived from polypropylene, a thermoplastic polymer, which means it is not biodegradable and can contribute to waste accumulation if not properly managed.

Compared to polyester, another nonwoven material, PP nonwoven has a lower carbon footprint due to its more energy-efficient production process. However, recycling PP nonwoven can be challenging, and advancements in recycling technologies are still needed to improve its sustainability.

2. Durability and Strength

PP Spunbond is known for its durability and resistance to tears and punctures, making it suitable for both short-term and long-term applications. In contrast, some other nonwoven materials may lack the same level of strength, especially in demanding environments like healthcare or agriculture.

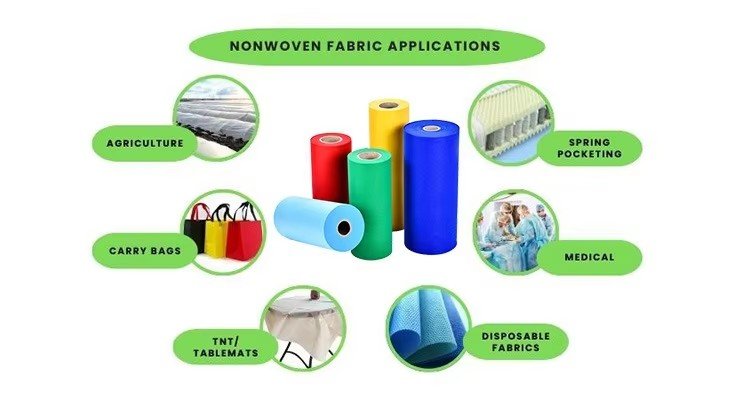

3. Versatility and Applications

PP Spunbond’s versatility is one of its greatest strengths. It is used in a wide range of industries, including:

-

Medical: Face masks, surgical gowns, and wound dressings.

-

Agriculture: Crop covers, weed control mats, and mulch films.

-

Industrial: Geotextiles, packaging, and filtration.

Other nonwoven materials may excel in specific applications but may not offer the same breadth of use as PP nonwoven .

4. Cost-Effectiveness

PP nonwoven is often more cost-effective than other nonwoven materials, especially for disposable products. Its affordability makes it a practical choice for industries looking to balance budget constraints with performance. In contrast, materials like woven fabrics may be more expensive upfront but offer long-term savings through reusability.

The Future of PP Spunbond and Sustainable Alternatives

As awareness of environmental impact grows, efforts are being made to develop more sustainable versions of PP nonwoven . Innovations in recycling technologies and the development of biodegradable nonwoven fabrics are promising steps towards reducing its environmental footprint. Additionally, consumers and industries are increasingly exploring alternatives like organic cotton or biodegradable polymers to meet sustainability goals.

Conclusion: Balancing Advantages with Environmental Responsibility

PP Spunbond remains a highly versatile and cost-effective nonwoven material with significant advantages across various industries. However, its environmental impact cannot be ignored. By continuing to innovate and explore sustainable alternatives, we can harness the benefits of PP nonwoven while minimizing its ecological footprint. The future of nonwoven materials lies in finding the right balance between performance, cost, and sustainability.

Keywords: PP Spunbond, Nonwoven Materials, Environmental Impact, Sustainability, Versatility